- Joined

- Sep 18, 2023

- Messages

- 1,983

- Reaction score

- 14

- Points

- 38

- Location

- Canada

- Website

- oneddl.org

- NullCash

- 54,940

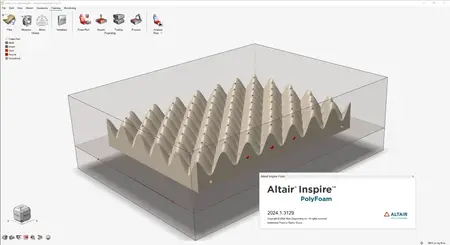

Free Download Altair Inspire PolyFoam 2024.1 | 4.6 Gb

Altairhas releasedInspire PolyFoam 2024.1is an essential toolset to simulate and validate the part design and physical processes that are required to create a polyurethane foam part

Owner:Altair

Product Name:Inspire PolyFoam

Version:2024.1

Supported Architectures:x64

Website Home Page :www.altair.com

Languages Supported:english

System Requirements:Windows *

Size:4.6 Gb.

New Features and Enhancements 2024.1

Altair Inspire PolyFoam 2024.1 includes the following new features and enhancements.

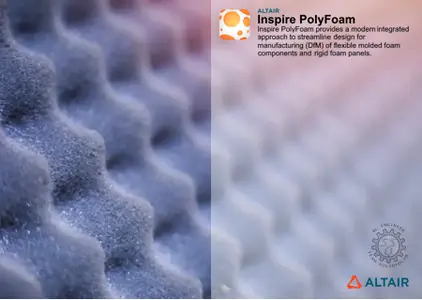

Material Characterization

This new feature lets you characterize materials using experimental data. You can obtain this data by measuring the rising and temperature profiles in a simple cup test. You can then use the data in PolyFoam to fully characterize a new material effortlessly, utilizing AI in the background.

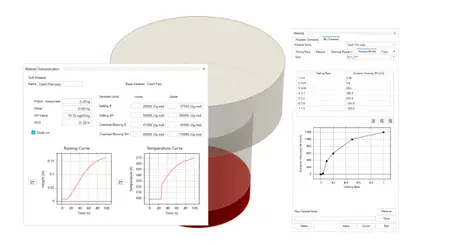

Mold Temperature Visualization Selection

The Mold Temperature result type is disabled by default to minimize simulation run time. You can re-enable the Mold Temperature result type in File → Preferences → Inspire Foam Analysis.

Improved Calculation Speed

Time step calculation algorithm and core scalability have been improved and calculation is now 10-20% faster in PolyFoam 2024.1.

Resolved Issues

Issues with respect to FSI analysis, subdivision shape detection, moving nozzle, and others have been resolved.

Inspire PolyFoamis the newest simulation analysis tool of Altair. It is an integral part of Inspire for manufacturing platform. With Inspire Polyfoam, learn and perform a mold filling simulation and evaluate design concepts. Inspire PolyFoam software predicts polyurethane reaction phenomena during the foaming process such as injection, foaming, curing and post-foaming considering chemical reactions and physical reactions. Inspire PolyFoam can predict the foaming pattern, heat and mass transfer including density distribution and temperature distribution according to the foaming component that affects the quality of the product.

Polyurethane Foam Simulation - Altair Inspire PolyFoam

Altairis a global technology company that provides software and cloud solutions in the areas of product development, high performance computing (HPC) and data analytics. Altair enables organizations across broad industry segments to compete more effectively in a connected world while creating a more sustainable future.

Rapidgator

http://peeplink.in/d6986862d19c

TakeFile

d7eo2.Altair-Inspire-PolyFoam-2024-1.part1.rar.html

d7eo2.Altair-Inspire-PolyFoam-2024-1.part2.rar.html

Fikper

d7eo2.Altair-Inspire-PolyFoam-2024-1.part1.rar.html

d7eo2.Altair-Inspire-PolyFoam-2024-1.part2.rar.html

Links are Interchangeable - No Password - Single Extraction