- Joined

- Sep 18, 2023

- Messages

- 2,417

- Reaction score

- 15

- Points

- 38

- Location

- Canada

- Website

- oneddl.org

- NullCash

- 66,478

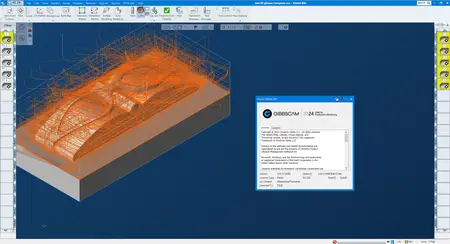

Free Download GibbsCAM 2024 v24.0.72.00 Win x64 Multilanguage | 36.4 Gb

Languages Supported: English, 汉语, 漢語, Čeština, Nederlands, Suomi,

Français, Deutsch, Italiano, 日本語, 한국어, Polski, Português,

Русский, Español, Español México, Svenska, Türkçe,

GibbsCAM, a leading CAD/CAM innovator in the production machining industry is pleased to announce the new software release.GibbsCAM 2024 (24.0.72.00) continues to boost end-user productivity for programming advanced machining centers, underpinning the GibbsCAM promise of Powerfully Simple, Simply Powerful.

Owner:GibbsCAM, a part Sandvik

Product Name:GibbsCAM

Version:2024 (24.0.72.00) with Tutorial Parts & Documentation PDF_english

Supported Architectures:x64

Website Home Page :www.cambrio.com

Languages Supported:multilanguage

System Requirements:Windows *

Size:36.4 Gb

GibbsCAM 2024 features a number of significant enhancements to core strengths while bringing a stronger emphasis on digital connectivity. Version 2024 unlocks the power of Sandvik Coromant through a direct integration with the CoroPlus Tool Library, providing access to the right cutting tool for your specific operation and offering instant cutting data recommendations. It provides up-to-date cutting tool data, 3D models of cutting tools and holders, and essential information to make informed decisions for optimized manufacturing processes. All data is verified and adheres to the ISO 13399 international standard for cutting tool data representation and exchange. The cloud-based nature of the tool library means that users of GibbsCAM 2024 can access data from anywhere with an internet connection, making it invaluable for organizations implementing company standards, or users who work remotely or across multiple locations.

GibbsCAMis designed to increase the efficiency and profitability of production machine shops with GibbsCAM toolpaths and post-processors that optimize the efficiency of the CNC machine. GibbsCAM integrates with all major CAD systems and supports 2 to 5-axis milling, turning, Swiss machining, multi-task machining (MTM), and wire-EDM.

GibbsCAM 2024continues to boost end-user productivity for programming advanced machining centers, underpinning the GibbsCAM promise of Powerfully Simple, Simply Powerful.

GibbsCAM Webinar : What's New in GibbsCAM 2024

During this fast-moving 45-minute webinar, GibbsCAM expert Bruce King will demonstrate what's new in version 2024, and highlight the new tools that make it easier to program with GibbsCAM than ever before.

Sandvik is a high-tech and global engineering group offering products and services that enhance customer productivity, profitability and sustainability. We hold world-leading positions in selected areas - tools and tooling systems for metal cutting; equipment and tools, service and technical solutions for the mining industry and rock excavation within the construction industry; products in advanced stainless steels and special alloys as well as products for industrial heating. In 2020, the Group had approximately 37,000 employees and revenues of about 86 billion SEK in more than 160 countries within continuing operations.

Sandvik has signed an agreement with Battery Ventures to acquire US-based CAMBRIO, a leading company with an end-to-end portfolio in CAD/CAM software for manufacturing industries like automotive, transportation, energy, medical and aerospace. CAMBRIO will be reported in the Design & Planning Automation division within Sandvik Manufacturing and Machining Solutions. By acquiring CAMBRIO, Sandvik will establish an important position in the CAM market that includes both toolmaking and general-purpose machining. This will complement the existing customer offering in Sandvik Manufacturing and Machining Solutions. CAMBRIO's product portfolio includes GibbsCAM for production milling, turning, and mill turn operations,Cimatron for mold and die, as well as SigmaNEST for sheet metal fabrication.

Rapidgator

http://peeplink.in/1eca7e4646a9

TakeFile

http://peeplink.in/20791e98b38e

Fikper

http://peeplink.in/b9a1b56458da

Links are Interchangeable - No Password - Single Extraction